CAPABILITIES

At Desitec, we are guided by principles of innovation, quality, and commitment. Our multidisciplinary approach allows us to offer advanced technological solutions that meet the specific needs of each sector in which we operate.

Solutions for the industry

We offer customised solutions for automation and control in the industry, focusing on improving operational efficiency and reducing environmental impact. We have experience in the food and agricultural sectors, where we have integrated our sensors into various production processes and designed automation systems to optimise control. Our projects include the implementation of systems for industrial ovens, pasteurisation vessels, and hydroponic gardens.

Products implemented

Temperature sensor

La reutilización del agua en lugar de utilizar agua dulce puede ser una buena forma de reducir el consumo de agua.

Pressure sensor

Hábitats con una huella mínima en el planeta y un impacto positivo máximo en la comunidad local.

pH sensor

Aprende a utilizar métodos de jardinería ecológica para cultivar los alimentos más frescos en tu huerto.

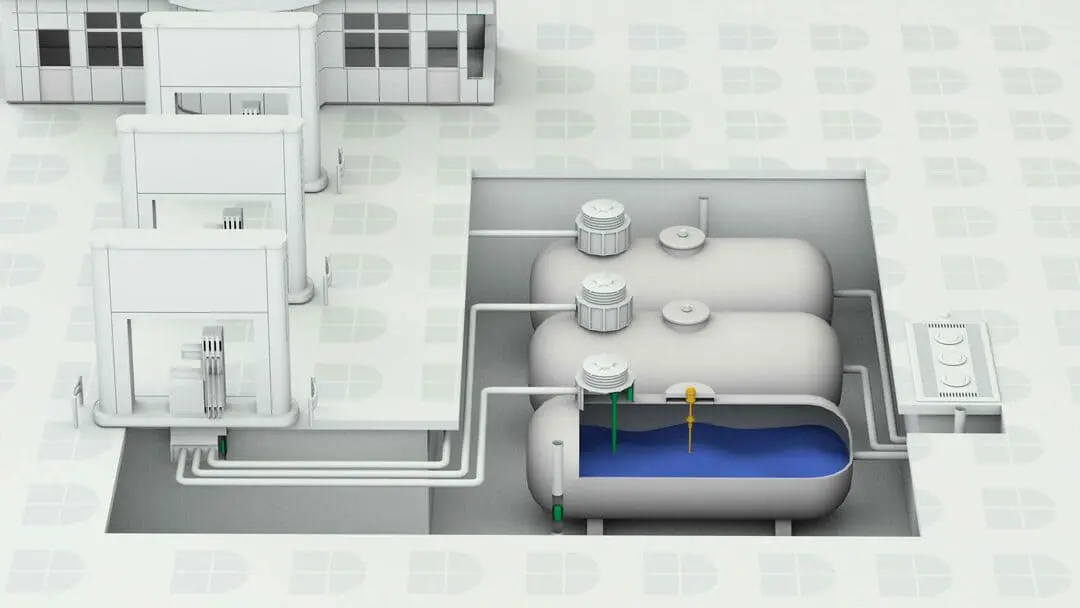

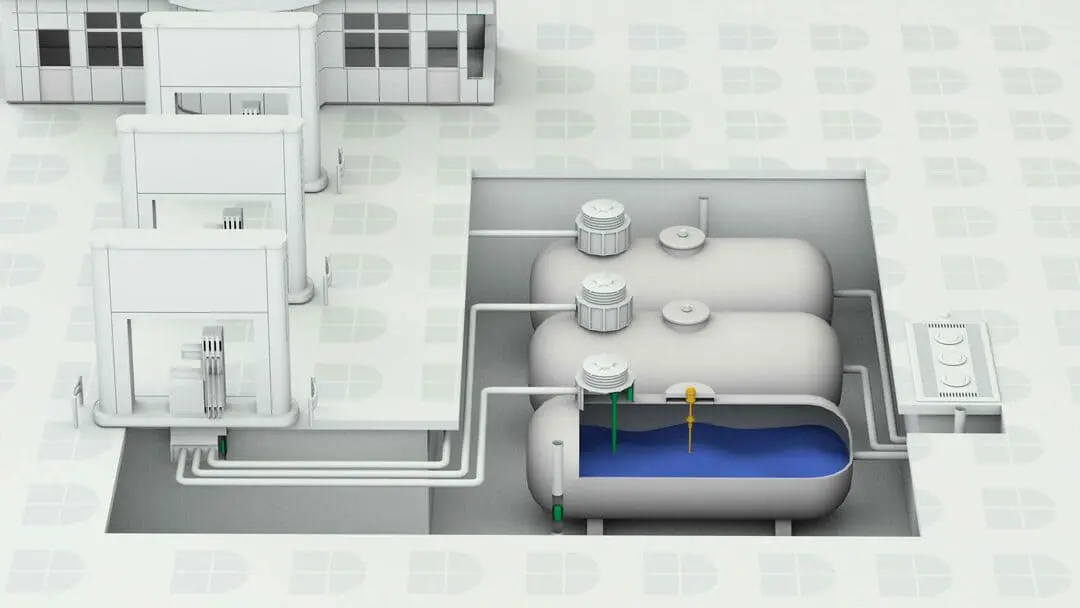

Control systems in Oil & Gas

We have extensive experience in the sector, working closely with service stations, refineries, mining companies, and vehicle fleets to provide highly accurate real-time monitoring and control systems, designed to ensure safety and operational efficiency in challenging environments. Our system integrates liquid level measurement, temperature, loss detection, and product quality in both above-ground and underground storage tanks. Additionally, we offer various sensors to prevent soil, stream, and groundwater contamination.

Our Products

Magnetostrictive probe

The magnetostrictive probes in the LEDA system allow real-time monitoring of fuel levels in tanks, eliminating the need for manual gauging and minimising errors. They use specific floaters to measure liquids and detect water, as well as temperature sensors for precise control. The system includes configurable alarms to warn of critical situations in the tanks.

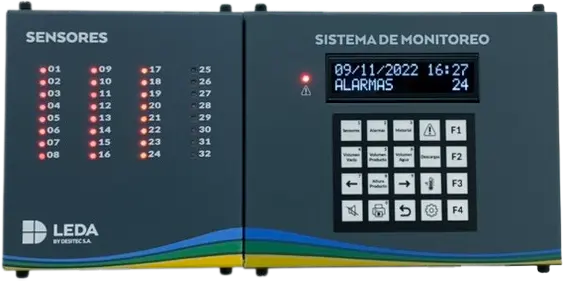

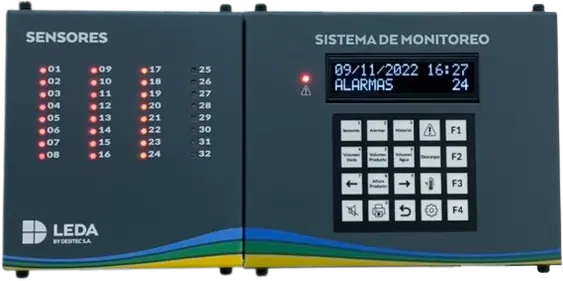

Console

LEDA consoles centralise the information from a loss control system, including both probes and sensors. The equipment meets the highest standards of quality and safety, being verified and tested according to protocols certified by INTI CITEI, under IRAM-IAP-IEC standards.

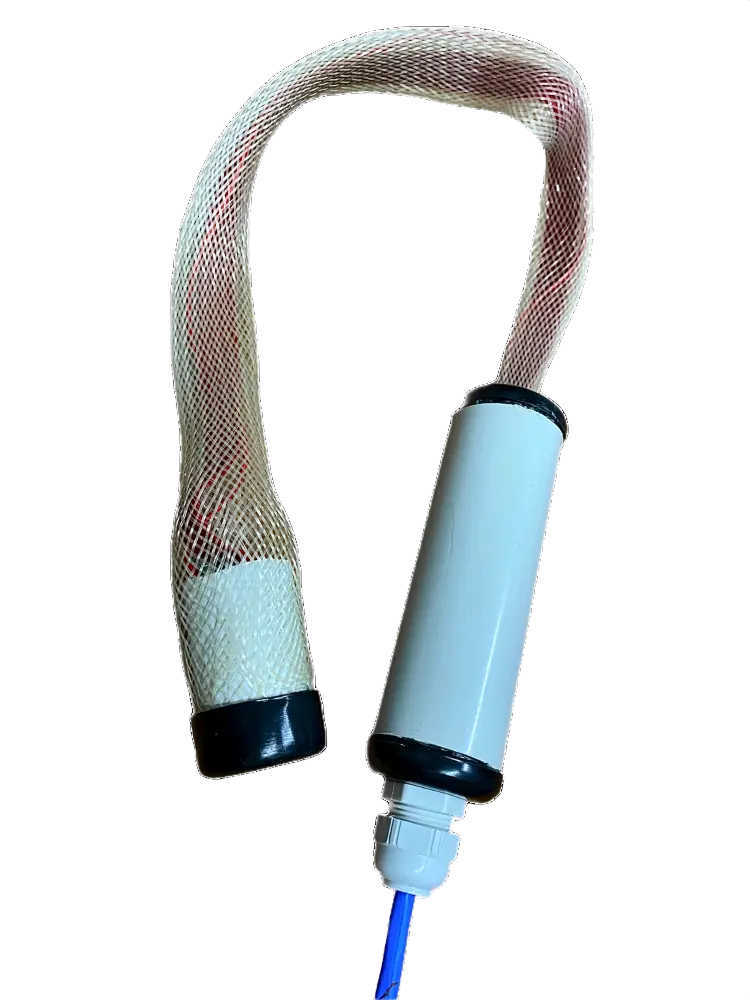

Liquid sensor

- Non-discriminating liquid sensor

- Easy maintenance

- Used in double walls, Sump Risers, Sump Dispensers (fuel dispensers), etc.

- Normally closed type

Groundwater sensor

- Fuel presence sensor (floating)

- It is located in a ground monitoring well with a high groundwater table level.

- Normally closed type

Vapor sensor

- Heated hydrocarbon gas sensor

- It is located in ground monitoring wells to identify potential fuel leaks.

- Normally closed type

Multiple level sensor

- Non-discriminating multiple liquid sensor

- Level positions customised to client request.

- Configuration of 2 to 5 levels.

- Normally closed type sensors.

- Maximum length of 3 meters.

Smart emissions control

We focus on providing advanced industrial solutions for the precise real-time measurement of the carbon footprint, helping companies efficiently and locally track their emissions. Our approach is aligned with international standards, enabling organisations to comply with environmental regulations and improve their social responsibility.

Technologies Employed

We employ a combination of advanced IoT sensors, real-time data analysis platforms, and automated reporting systems to provide a clear and precise view of carbon emissions. These tools enable companies to identify areas for improvement and reduce their environmental impact.

Work Process

We start by understanding the specific needs of each client, conducting a detailed assessment of their operations. We then design and implement a customised carbon footprint measurement system that fits perfectly with their existing sectors and processes. Our after-sales support ensures the long-term effectiveness of our solutions, their evolution alongside our clients, and their updates in line with new regulations and technologies.

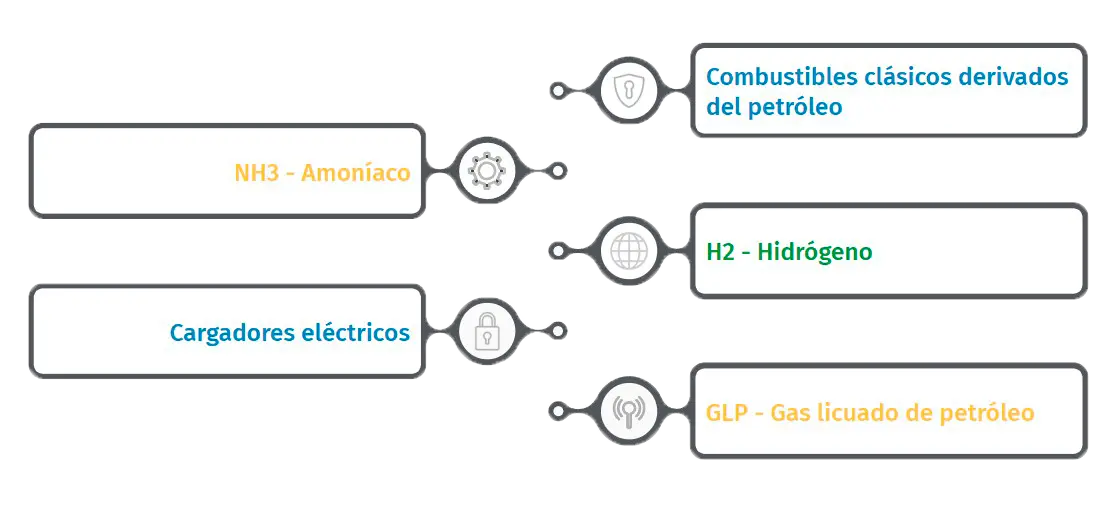

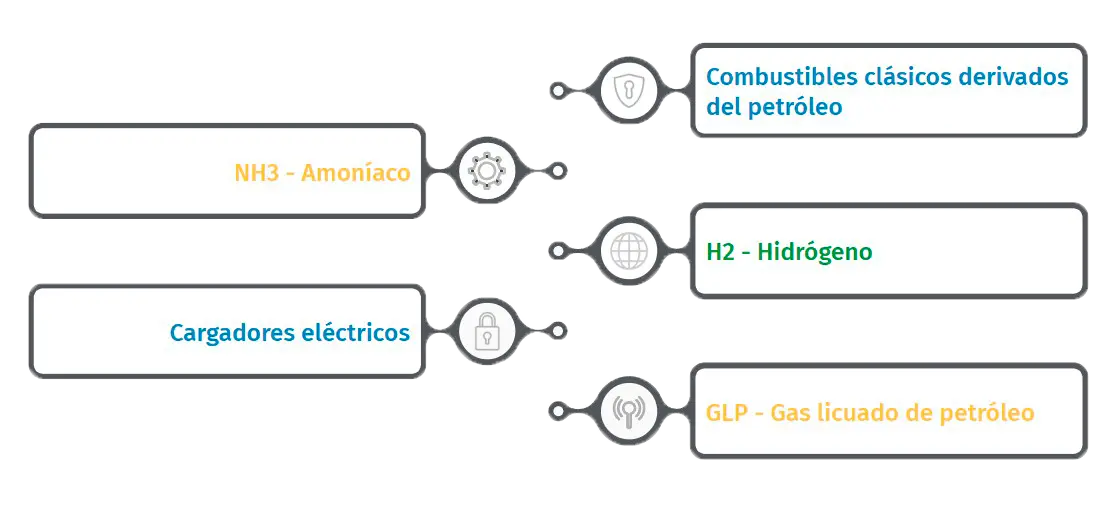

Developing solutions for new energies

Our systems integrate unified control for a wide range of fuels, including petroleum derivatives, ammonia, hydrogen, electricity, and liquefied petroleum gas. We anticipate the needs of the future energy landscape, ensuring that our solutions are ready for the fuel stations of tomorrow.

Designing the energy future

At Desitec, we are ready to lead a swift transition towards cleaner and more sustainable energy, providing technological solutions that drive the efficiency and safety of these new energy forms.

Innovation and energy sustainability

In a global context where environmental impact and the search for alternative energy sources to petroleum have become priorities, Desitec remains at the forefront. We maintain direct engagement with these new energy sources, leveraging our technology and expertise to facilitate their adoption, ensuring comprehensive control and reliable safety across the entire system.

Solutions for the industry

Ofrecemos soluciones personalizadas para la automatización y control de distintos procesos en la industria, enfocándonos en mejorar la eficiencia operativa y reducir el impacto ambiental. Nos especializamos en adaptar nuestras tecnologías a las necesidades específicas de cada cliente, utilizando sistemas avanzados que optimizan el rendimiento de los procesos productivos.

Experiencia en el ámbito industrial

Tenemos experiencia en sectores como el agrícola, alimentario y energético, implementando distintos sensores de presión, temperatura y pH. Estos sensores se han utilizado en la optimización de procesos como hornos industriales, pasteurizadoras, jardines hidropónicos y tanques de destilación, contribuyendo a un mayor control y eficiencia en cada aplicación.

Integración y control centralizado

Todos estos sensores son controlados por electrónica desarrollada por nosotros, la cual se comunica directamente con nuestro sistema centralizado. Este sistema recopila los datos generados por los sensores, los analiza y los presenta al usuario en tiempo real, permitiendo una operación más eficiente y precisa basada en la mejor información disponible.

Control systems in Oil & Gas

We have extensive experience in the sector, working closely with service stations, refineries, mining companies, and vehicle fleets to provide highly accurate real-time monitoring and control systems, designed to ensure safety and operational efficiency in challenging environments. Our system integrates liquid level measurement, temperature, loss detection, and product quality in both above-ground and underground storage tanks. Additionally, we offer various sensors to prevent soil, stream, and groundwater contamination.

Our Products

Console

Concentra la información de un sistema de control de pérdidas, tanto de sondas como sensores conectados. Cumplen con los más altos estándares de calidad y seguridad, de acuerdo a protocolos certificados por INTI CITEI, bajo normas IRAM-IAP-IEC. Diseño modular con frentes intercambiables (Impresora, leds, táctil, display y teclado). Permite interconexión para su expansión.

Conectividad a la red local y visualización web en tiempo real.

Liquid sensor

- Non-discriminating liquid sensor

- Detección temprana de fugas.

- Sencilla instalación, control y mantenimiento.

- Utilizado en Doble Pared, Sump Risers, Sump Dispensers (surtidores), etc.

- Normally closed type

- Modelo SDL-1 para hidrocarburos, SDL-U para urea/azul 32.

Magnetostrictive probe

- Permiten monitorear en tiempo real:

- Nivel de producto (en milímetros y

litros) y detección de agua.

- Nivel de fase (expresado en mm).

- Temperatura del producto.

- Incluye alarmas configurables para advertir sobre situaciones críticas.

- Precisión ±1mm.

- Protocolo de comunicación RS-485 y/o Modbus.

Sensor de terreno vapor

- Detección de presencia de vapores de hidrocarburo (diésel, fuel oil, naftas sin plomo, naftas sintéticas, JP1 y JP4) y gases combustibles (H2, CH4, entre otros).

- Se instalan en los pozos de monitoreo de terreno.

- De estado sólido, metal óxido semiconductor (MOS). Tipo normal cerrado.

Sensor de terreno napa

- Detección de hidrocarburos líquidos en lugares donde se acumula agua.

- Se ubica en pozo de monitoreo de terreno con nivel de napa freática alta, en baterías de tanques y en batea de contención de tanques aéreos, bombas y tuberías.

- Normally closed type

Multiple level sensor

- Sensor múltiple no discriminador de líquido.

- Monitorea presencia de líquidos, diseñado para operar en presencia de combustibles.

- Posición y configuración de 2 a 5 niveles.

- Longitud máxima de 3 metros.

- Tipo de contacto: normal cerrado o abierto, a solicitud del cliente.

Smart emissions control

We focus on providing advanced industrial solutions for the precise real-time measurement of the carbon footprint, helping companies efficiently and locally track their emissions. Our approach is aligned with international standards, enabling organisations to comply with environmental regulations and improve their social responsibility.

Technologies Employed

We employ a combination of advanced IoT sensors, real-time data analysis platforms, and automated reporting systems to provide a clear and precise view of carbon emissions. These tools enable companies to identify areas for improvement and reduce their environmental impact.

Work Process

We start by understanding the specific needs of each client, conducting a detailed assessment of their operations. We then design and implement a customised carbon footprint measurement system that fits perfectly with their existing sectors and processes. Our after-sales support ensures the long-term effectiveness of our solutions, their evolution alongside our clients, and their updates in line with new regulations and technologies.

Innovation and energy sustainability

In a global context where environmental impact and the search for alternative energy sources to petroleum have become priorities, Desitec remains at the forefront. We maintain direct engagement with these new energy sources, leveraging our technology and expertise to facilitate their adoption, ensuring comprehensive control and reliable safety across the entire system.

Developing solutions for new energies

Our systems integrate unified control for a wide range of fuels, including petroleum derivatives, ammonia, hydrogen, electricity, and liquefied petroleum gas. We anticipate the needs of the future energy landscape, ensuring that our solutions are ready for the fuel stations of tomorrow.

Designing the energy future

At Desitec, we are ready to lead a swift transition towards cleaner and more sustainable energy, providing technological solutions that drive the efficiency and safety of these new energy forms.

Request detailed information about our products and services

We have high quality advice to optimize your business